Lightning Master® offers a full line of surge suppressors for industrial and commercial use. Lightning Master designed these units in-house to meet the needs of our Customers.

The Lightning Master surge protection line was designed with heavy-duty industrial users in mind. LMC surge suppression devices provide surge and transient protection in the harshest of environments, preventing costly outages and downtime at your critical facilities. Protect your investment with Lightning Master.

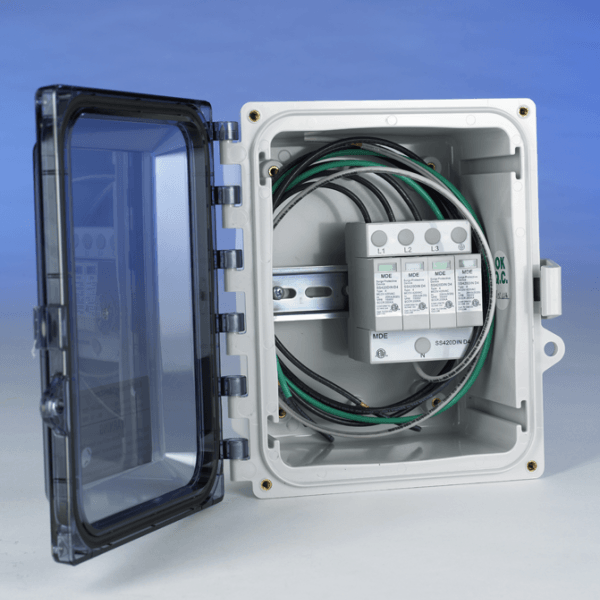

AC POWER

The Lightning Master surge protection line was designed with heavy-duty industrial users in mind. LMC surge suppression devices provide surge and transient protection in the harshest of environments, preventing costly outages and downtime at your critical facilities. Protect your investment with Lightning Master.

Low-Voltage – 120V-600 VAC

• install directly at a disconnect or sub-distribution panel

• modular – once wired in, individual modules may be changed without re-wiring

• only two units – one type covers 120-240V, and a second covers 240-480V;a second module covers high-leg services

A big problem in AC power surge suppression installation is that few customers know the voltage and configuration of their power. If you ask, a customer will likely reply that it is 600V, merely giving you the maximum rating of an enclosure. With other surge suppression brands, you have to know the exact type of power, i.e., 120/240V split phase, 120/208V 3ø, 240V hi-leg delta, etc., and you must have the correct model with you to complete the installation. With Lightning Master suppressors, you only need two boxes and one extra module on your truck to cover all possible voltages. One model covers everything from 120-240, and a second model covers 240-480V. The extra module covers a high leg.

Medium Voltage – 660V-4, 160VAC

• designed to protect medium voltage equipment, particularly motors

• robust, yet compact design

• manufactured in LMC’s Clearwater, FL shop

DATA

Lightning Master offers hard-wire, DIN rail, and in-conduit models from 6 – 120 VDC. Our models are competitively priced and readily available. All models may be custom-designed for different voltages on different terminals, as we make them ourselves.

Lightning Master designed its line of data surge suppressors to meet the needs of its industrial Customers. We offer two versions to be installed at the CPU end: 1) a 12 wire terminal strip (TS-12-xx), and 2) a 12 wire DIN-rail mounted unit (LM-DIN-12-xx). For the transmitter end, we offer an in-the-conduit 4 wire unit (LM-PC-4-xx). We refer to this model as a “pipe cleaner”, as it is installed in the conduit immediately before the transmitter or other load. In all model numbers, the xx is the voltage on the wires, i.e., 6, 12, 24, 48, 120.

All of our units incorporate geometry in the traces to increase the impedance through the device to the load under protection and present a lower impedance through the surge suppression components.

Our pipe cleaners protect four wires. During the design of this unit, we realized that we had sufficient room on the board for four traces. The cost of populating four traces was not much greater than protecting only two. Most SCADA systems only use two wires. This way, once the unit is installed, if the two traces initially used are damaged by a transient, one simply moves the wires to the two unused and undamaged traces. If effect, you get two surge suppressors for the price of one, plus you do not have to reinstall a new unit in the conduit.

An additional feature of our pipe cleaner unit is ground-to-ground protection for the shield wire. In most installations, the shield wire is grounded at the CPU end and floated at the field end to eliminate noise. This is generally fine, except if a technician is working on the transmitter, touching the shield wire while also in contact with another locally grounded component. As the shield wire is grounded some distance away, if there is an AC power ground fault or some other condition that causes a change in potential of the shield wire vis-à-vis the local ground at the transmitter, the technician would be the path of equalization, resulting in an electrical shock. With our pipe cleaner, the shield is attached to a terminal screw in the pipe cleaner. That screw is normally floating, but equipped with a mode of surge suppression to ground. If the voltage difference between the shield wire and the transmitter (local ground) exceeds 70 volts or so, the surge suppressor clamps and the technician is protected.

LOAD CELL

When we first started doing business in the batch process industry, we were appalled at the technology used in load cell surge suppressors. So we designed our own. Our design includes using geometry in the traces to increase the impedance through the device to the load under protection and present a lower impedance through the surge suppression components. We also protect 8 wires instead of the normal 4, providing backup traces in the event in-use traces are damaged.

Testimonial

“Had it not been for the SPD system, the electrical

system would have been completely destroyed and

quite possible could have caught on fire.”

Facility Manager, Department of the Army